July 04 2022

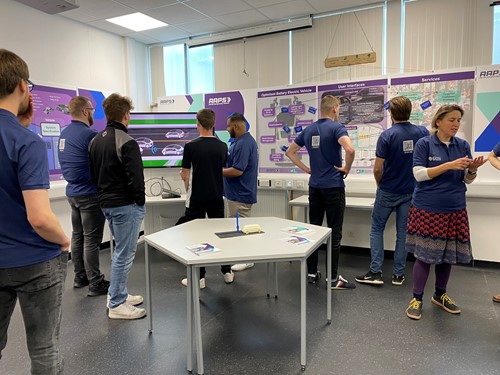

The road to the Mechanical Engineering design and project exhibition started all the way back in November 2021 where our idea for a holistically sustainable mobility ecosystem was first conceived. The idea came from a thorough review of the technical challenges facing automotive OEMs and the social constructs which we found to hinder the rate of decarbonisation of private transportation. In the months that followed, our cohort developed this idea into an ecosystem, which, incorporated a range of vehicles and services which were designed to work in unison to ultimately reduce private car ownership. Building such an intricate proposal for the design exhibition provided a few hurdles when it came to presenting to an audience with no prior knowledge of the ecosystem, but we’ll come back to those later.

Forming part of the innovation module of the MRes year, the exhibition stood alongside a report and presentation to form the three assessed outputs of the unit. With that in mind, as a cohort we decided to present our work in 3 distinct methods, tailoring the content to the delivery method. With the report being technical and the presentation being more business and use case focussed, we were left with a dilemma as to how to convey the months of work we’d completed to someone with no prior knowledge. Luckily, as the cohort had worked together to make the high level decisions for our ecosystem’s design, we were all able to explain the intricacies and nuances behind our design. We felt like a content heavy exhibition would be too taxing on the audience, and instead decided to display the method behind our design formulation: systems thinking.

Now coming back to those hurdles I mentioned earlier.

Being the first in person design exhibition that the CDT has participated in, we decided to push the boat out with our exhibit. During the brainstorming phase, our focus was on the content of the posters and how to communicate the systems thinking process. We ultimately decided on 9 A1 posters and a storyboard style format to guide the audience though the design process. In addition to the posters, we wanted to introduce some interactive aspects to the exhibit to support the narrative.

The first port of call was to film 90 second elevator pitch style segments from the cohort each giving an overview of their specific section of the ecosystem design. This would end up being played as a rolling loop on a couple of monitors midway through the poster story board. A mood board also joined the elevator pitches on another screen to split the story board even further to give the audience a glimpse into our motivations behind the design of the vehicles.

Next on the list of interactive aspects was 3D printed model of our vehicles and charging solutions. Given the tight schedule we were working with, it was imperative that nothing drastic should go wrong, but it turns out 3D printing is a little more complicated than I initially thought, and I ended up only getting the models completed the morning of the exhibition (I won’t be making that mistake again!). Ultimately, it took 5 designs and multiple iterations to create a model which wouldn’t implode under its own weight. Stress.

Back to the posters, which we were assuming to be A1 in size (we were wrong), we thought they could do with a nicely painted backing plate to make them free standing – as no one wants flimsy posters at an exhibition. The plan was to buy MDF backing boards and to paint them with an AAPS branded paint, obviously this was the next thing to go wrong. Having scoured the local hardware stores for a couple of days for enough MDF for the posters as well as the right shade to paint them, a collective effort from the cohort saw the boards painted by 7pm 3 days before the exhibition. It later transpired that the posters were in fact self-standing and A0; noticeably larger than the backing boards we spent days sourcing and painting. This was really a blessing in disguise, as the larger posters filled the vast space we were given perfectly. A selection of premium chocolates were also procured to entice visitors to our exhibit (not that they could miss it given we took up a quarter of the room). And the last piece to tie up our exhibit was matching polo shirts for our cohort, with the icing on the cake being the QR codes printed on the back which led to our page on the AAPS website. An idea so ingenious that everyone in the CDT eventually ended up with their own polo shirts (you’re welcome Jess).

When it came time to explain the ecosystem and the methods we used to arrive at our final product, the matching polos perfectly symbolised the cohesion that the cohort displayed when talking through the proposal. Though it sounds a bit cliché, the cohort embodied the T model of knowledge down to….well a T. Everyone was able to thoroughly explain the fundamentals of the proposal to the audience and then point in the direction of the suitable cohort member if there were specific follow up questions.

Special mentions go out to Josh and Gary from 3D printing for putting up with my naivety when it came to making the models, and Jess (our Student Experience and Programmes Officer) for arguably being just as excited as us for the exhibition and designing the breaks for the story board. Lastly, it goes without saying that without the contributions of each member of the cohort, there was no way we could’ve pulled off such an ambitious exhibit.

28 February 2024

18 January 2024

29 November 2023

13 November 2023

© Copyright 2024 AAPS CDT, Centre for Doctoral Training in Advanced Automotive Propulsion Systems at the University of Bath