September 18 2023

Towards the end of my second year of the PhD I took a pause of studies for three months to take up a Research Assistant position in the Institute for Mathematical Innovation here at the University of Bath. I worked alongside academics in the department of mechanical engineering as part of the NCForm project to develop a simplified model for predicting wrinkling during the manufacture of non-crimp fabric (NCF) composite materials, building upon an existing body of work here at the university.

NCF composites consist of a stack of individual plies (layers of fabric in which all the fibres are oriented in the same direction) laid on top of each other. They are formed into the desired shape and then cured to harden. Applications include aerospace structures such as wings, where light but strong materials are required. The name "non-crimp" comes from the fact that the fibres lay flat on top of each other and are not woven together (and so do not go in and out like a crimp!) as in many other fabrics such as clothing.

Typically NCF composites are currently made by hand-laying each ply on top of the previous until the desired material specification is reached. This is a time-consuming process but leads to high-quality parts with few defects. Newer approaches such as double-diaphragm forming (DDF) explained below, are faster but can be prone to wrinkling and defects in the finished product. Such problems can lead to structural weakness and, depending on the severity, can result in the part needing to be made again from scratch.

The aim of our research was to devise a much-simplified model of the DDF forming process to be able to predict whether we would expect wrinkling or not, based on only a small set of parameters. This would be of use to designers as a first step in the design process, before higher-fidelity simulation and physical testing can take place. Whether wrinkling will occur depends on several factors including the shape of the part, the number of plies being laid, and the orientation of those plies. The DDF process begins by stacking multiple plies on top of each other, usually in various orientations to increase strength in different directions. The stack is compressed together inside a vacuum bag and is then lowered down over the tool surface (something akin to a mould) to give the desired geometry to the part. A second vacuum then draws the stack in towards the tool surface to further compress it before curing, when the material hardens.

In the course of the three months we were able to bring together the existing work and implement a fast initial-test model to predict whether wrinkling would occur for a given setup. The advantage of this compared to other methods is the speed; physical testing and high-fidelity simulations can take days or weeks to give results. On the other hand, it takes our model seconds to run, meaning that for the same amount of time many more experiments can be carried out. The trade off is in accuracy. We have made many assumptions and simplifications to achieve this speed. Whilst the model gives ballpark predictions, it is only supposed to act as an initial filter for potentially bad (or good) experimental setups.

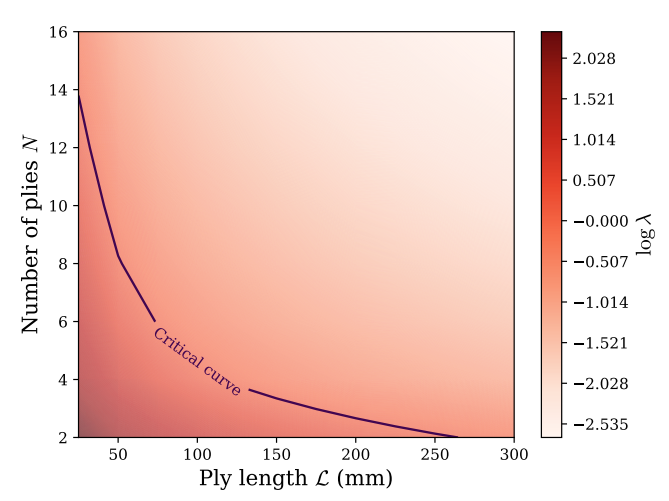

The figure shows a carpet plot depicting the formability of one test case with fixed parameters except for the number of plies in the stack and the length of the plies. The critical curve shows the cutoff where we would expect wrinkling - above the curve we predict wrinkling to occur and below we do not. This is just one example of how the model can be used, and it took only a couple of minutes to run the code for all test cases and generate the plot.

The target output of the research is a publication, which we are currently in the process of writing. It has been a good experience to work alongside academics from another discipline and get an insight into how different disciplines view the same problem in their own way (very much in the spirit of AAPS!). I must admit I was surprised by the differences at first, and it took a little while at the start for us to find a common language to be able to understand each other. Also, whilst not being wildly dissimilar, there are a few differences between engineering papers and those in maths, which typically follow a theorem-proof structure.

A plot demonatrating the potential use case for the developed model in predicting wrinkling. Setups with a given number of plies or ply length above and to the right of the critical curve are predicted to wrinkle, whereas those below and to the left are predicted to be formable without wrinkling.

Overall I found the experience enlightening, and it was nice to have a break from the PhD for a while too. I would recommend considering a short placement like this if you want to explore a different area or get a new experience - even if you decide it isn't what you want afterwards, what is three months in the grand scheme of things!

28 February 2024

18 January 2024

29 November 2023

13 November 2023

© Copyright 2024 AAPS CDT, Centre for Doctoral Training in Advanced Automotive Propulsion Systems at the University of Bath