Vehicle development is a complex and demanding process that requires a lot of blood, sweat and tears. Over the next two blogs I will provide a closer insight into first how Dr. Ettore Lappano showed us the motivations for and second the transformation of the vehicle development process at AVL.

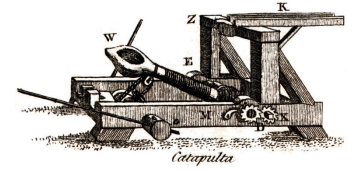

Starting with a group exercise we travelled back in time a couple of centuries to become the inventors of a novel ballistic device. One that would allow our emperor to destroy enemy rampart, gain supremacy and conquer the world. This might be a very bad description of what some might already guess is the catapult, I agree. However, it is probably quite close to what woodworkers and masons back then had, as description of what the emperor wanted.

Knowing our resources were limited, we identified the only things available being just potential energy and any natural material and objects we could get hold off. The development could begin.

Having seen a bunch of medieval movies, featuring more than one successful siege, working from the initial requests we started to discuss the design. Some of the key properties we believed would be the key to our catapult being an undisputed success were long range, mobility, two-manned operation, ease of repair and ease of assembly. It struck us hard when we found out that these were some of the common ones occurring across all the groups. Quickly realising that successfully pitching our new design to the emperor, the key to his supremacy, will be extremely difficult and we better revolutionise our design to keep our heads on our necks.

Scared for our lives we begun to think about how we could test the performance of our design and see whether it works as expected, identify imperfections, and improve upon them. Ideas to simulate it started to emerge almost immediately. Unfortunately, we had hard times recalling medieval movie scenes with computers running a Simulink model and we therefore reverted to plan B, physical testing. This seemed to be the only way despite the extra delay and costs to both the delivery of our system and the next campaign. There was no other option. The pressure was on, and competition fierce. Thankfully, Ettore stopped us right there.

At first sight this might seem like a childish exercise with an on-the-spot made up development process. Some might however be able to spot some core features of the traditional V-process. We went from conceptualising the system, through its development to achieve a timely and successful delivery. In this simple, 15-minute exercise, the aim of the work that Ettores’ team does became very clear.

Moving away from a simple catapult to modern vehicles the differences are obvious. Computers, motors, batteries and ADAS systems all increase the system complexity and demands on engineering teams. Some of the core processes however remain very similar. The traditional development process seems to be too good to be moved away from completely but not good enough to be followed precisely.

To be able to meet the requirements of the fast changing and competitive environment of today Ettore shed some light on how his team is dealing with these challenges. I will dive into more detail in the next blog.